Researchers developed a chemical to revive dead lithium batteries

Researchers from Toyota Central and R&D Labs in Japan have developed a chemical to revive dead lithium batteries. Even though lithium batteries are reusable, their energy storage capacity eventually runs out.

However, Toyota researchers discovered a method to reverse the process and revive dead lithium batteries like an energy drink for a car’s battery.

As standard lithium-based batteries gradually lose particles known as “lithium ions.” Hence, they cannot hold as much charge. So, researchers developed a chemical known as a “recovery reagent” which they could inject into a dead battery to revitalize it.

Following this process, the battery’s lithium ions are restored through a chemical reaction initiated by the recovery reagent. Then, the battery is ready for use.

The lead researcher of this experiment, Nobuhiro Ogihara revealed they verified the effectiveness of this method not only with small-sized batteries for lab use. But, it also proved helpful for large batteries for automotive use.

Lithium batteries power electric vehicles and several other modern devices. However, the rare elements used to make these batteries. It makes them hard to revive once they reach their life cycle.

Hence, researchers to find methods to recycle wasted lithium batteries into new ones or replace lithium with a new form of battery requires more abundant materials. Moreover, it costs millions of dollars and countless hours of labor.

Recycling is a long-term solution that offers benefits. However, reviving the dead lithium battery’s process by recovery reagent may restore up to 80% of their lost capacity without replacing it.

It significantly extends its useful life, which might result in significant costs for owners and manufacturers. It may also decrease the demand for new lithium mining, which is environmentally damaging. Hence, it helps reduce the negative environmental effects associated with mining activities.

Read More:

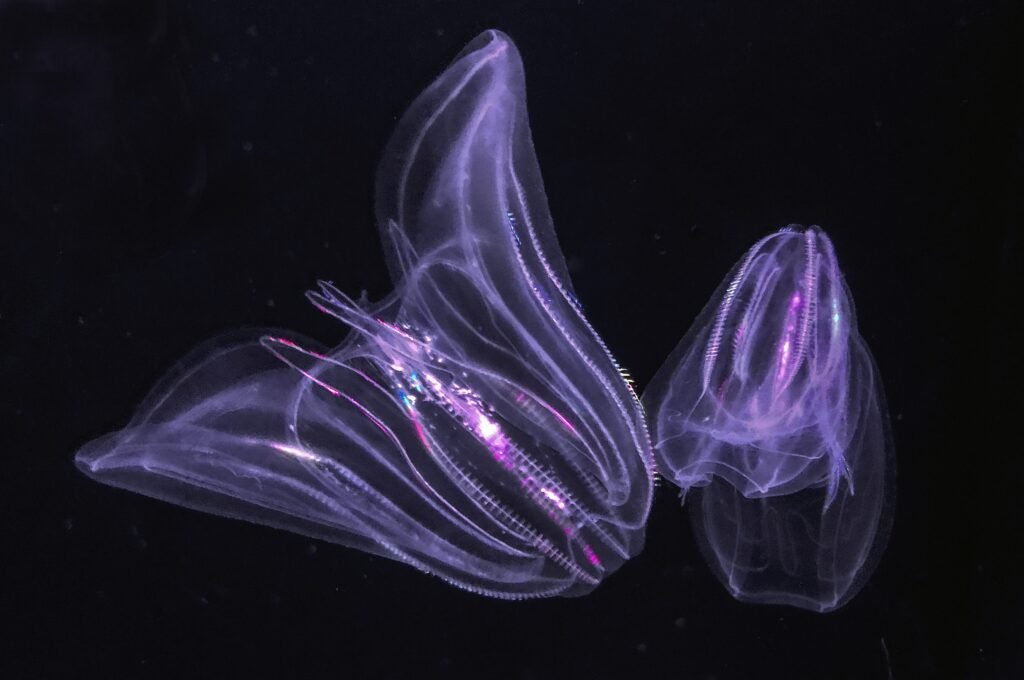

- Sea creature turns into a baby when it is stressed out showing time travel

- Realme Narzo 70 Turbo 5G launch date, features, specifications & price

- European Space Agency printed 3D metal part in space for first time

- Earth’s mysterious Alaska triangle where over 20,000 people disappeared

- Philips Hue launched a new smart lighting solution for kitchen

- NASA to launch life-searching spacecraft to Jupiter’s moon Europa

Share this content:

Post Comment